Tooling & Consumables

Tooling & Consumables

Print cylinders

Description:

Our print cylinders are made of special aluminum material or steel. The working surface can be anodized to protect it from scratching. The plate cylinders can be made of tube to reduce the weight. All cylinders are supplied with standard gears, but for better quality of print we can also supply it with hardened and ground gear. Rotometal manufactures printing cylinders for all flexo machines.

Technical data:

- High accuracy

- Scratch proof

- Horizontal and vertical guide lines for easy plate assembly

- Short manufacturing lead time

- Repair service on customer request

Magnetic cylinders

Description:

Magnetic cylinders are manufactured to a high quality standard that assures accuracy and consistency of the final product. Body made from nonmagnetic stainless steel provides an excellent protection against corrosion, does not deprive the strength of magnet power and enables high and equal adhesion of flexible die during use. Bearers made from high quality tool steel hardened above 60 HRC ensure long term and trouble-free performance. Optimum grip of flexible die is obtained by using ferrite magnets. For special jobs and better adhesion, strong neodymium magnets are recommended as an alternative or additional option. The light weight of the magnetic roll is also possible when the body is made from aluminum or is hollow inside. Minimum gap size tolerances guarantee the highest precision of cutting.

Technical data:

- diameter up to 360 mm

- total length up to 2000 mm

- total weight up to 300 kg

- can be made with pins to protect the flexible die from displacement

- available also as special HMT cylinder made of aluminium or stainless steel with the magnets hidden inside

- customized repair service on customer request

- scribe line for easy applying of flexible die

- maximum axial runout accuracy +/- 0,003 mm

- short manufacturing lead time

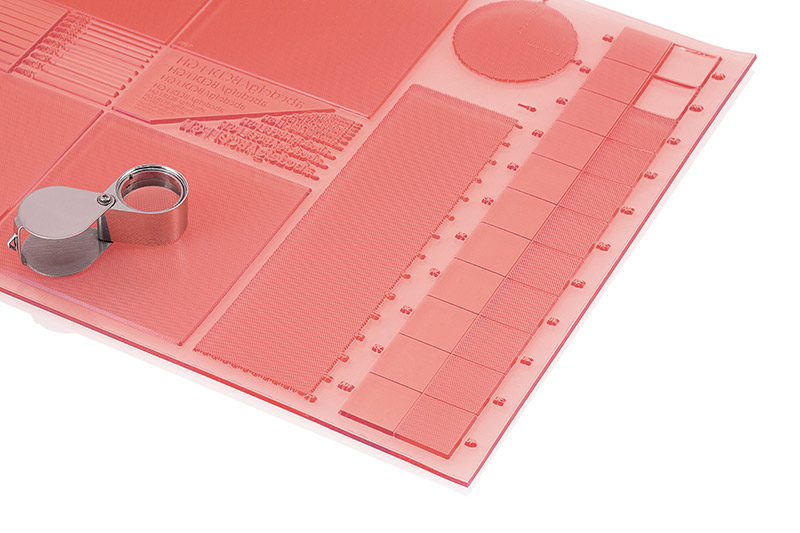

AFP™-SE/DSE

Solid Photopolymer – Soft type plate available in analogue and digital

The AFP™-SE/DSE flexo plate meets the most demanding criteria of quality in printing corrugated board, solid board and heavy-duty bags. Its ideal shore hardness and resilience characteristics compensate for the surface unevenness of the substrate. Its dimensionally stable polyester base sheet adds to its ability to achieve very high quality, while the wide exposure latitude of the AFP™-SE/DSE plate ensures that image elements like tones and isolated lines are optimally anchored even with a relief depth of 3 mm.

Benefits:

- Low dot gain printing & excellent ink transfer.

- Optimized plate resilience to minimize a washboard effect.

- Optimized durability for highly aggressive papers.

- Optimum intermediate depths with steep relief shoulders.

- Compatible with recent screening and microcell technologies.

AFP™-SF/DSF

Medium hard plate available for analog and digital

The AFP™-SF/DSF is Asahi’s medium hard plate that elevates printing results to a new level of quality. It is designed for good highlights combined with excellent ink transfer onto all substrates. Its optimized balance of solid ink laydown and highlight dot printing produces incomparably good ink coverage with low dot gain in the mid tones and brilliant highlights at maximum printing speeds, with particular suitability for flexible packaging printing on film and paper with solvent or water based inks.

Benefits:

- Superbly balanced reproduction of large tonal areas, text and halftone elements.

- Wide exposure latitude enables consistent results.

- Steep relief shoulders and very good intermediate depths result in minimal dot gain.

- Its flexibility makes it possible to print with small-diameter cylinders.

- AFP™-SF/DSF is the perfect choice for solvent- and water-based ink printing applications where solid ink transfer in harmony with fine highlight dots is the focus.

AFP™-TOP

The premium flexo plate with CleanPrint

Asahi‘s AFP™-TOP is a hard premium digital flexo plate delivers a broad colour gamut and soft tonal shades fading out to zero. Asahi‘s AFP™-TOP incorporates CleanPrint with a kiss touch printing pressure setting that facilitates constant repeatability of printing quality during the production run, longer plate life and fewer cleaning intervals and press stop downtimes.

Asahi‘s AFP™-TOP plate is compatible with many of the recent high definition screening and microcell patterning technologies.

Benefits:

- Produces high resolution images with excellent printing performance.

- Broad colour gamut due to low dot gain and enhanced ink transfer.

- High performance printing with solvent-, water- and UV-based inks on film, coated paper and label substrates.

- Consistent printing quality over the entire production run with CleanPrint.

- Fits into existing solvent plate making workflow with no extra equipment investment.

UNI SUPERIOR

Universal surface and lamination ink series with high pigmentation based on nitrocellulose/polyurethane designed for flexo and gravure applications.

Application and printing substrates

Surface printing on corona treated LDPE, HDPE; different types of corona treated PP: OPP, BOPP, CPP; primed metalized PP; primed metal foil. Lamination ink to produce different laminates based on PP, PE and chemically treated PET.

Ink properties:

- high adhesion;

- excellent printability;

- high transparency;

- high gloss;

- dry rub resistance;

- high temperature resistance of the ink film in the process of packaging fabrication;

- chemical resistance to acid and water (on requirement inks with enhanced light, alkali and other resistances can be produced to meet particular specifications);

- on request heat resistant pigments can be used for ink production;

- shipping viscosity min. 30 sec. (Government Standard # 8420: viscometer VS-246 at 20±0,5ºС, 4 mm cup), on requirement ink viscosity can be adjusted.

High end anilox rollers and sleeves identified by unsurpassed quality of ceramic coating. Cell profiles are engraved by fiber laser with changeable optics and modulation, due to that even standard applications stand out in terms of optimal cell geometry.

The product and service range of PAKTEAM includes:

- new anilox rollers and sleeves

- refurbishment services along with complete reconstruction of the anilox

PAKTEAM offers standard engravings and as well Hybrid engravings developed for different kind of applications. These engravings allow an optimized transfer to the plate.

The Trupoint Doctor Blade Advantage

Facilities all around the world have switched to TruPoint plastic doctor blades for the quality, safety and innovation of TruPoint blades, as well as the amazing level of service and technical expertise.

Compared to Traditional Steel Doctor Blades, TruPoint Plastic Doctor Blades:

- Extend Doctor Blade Life

- Eliminate Anilox Roll Scoring & Premature Wear

- Improve Safety in your Facility

RED LABEL printing doctor blades

High carbon steel

- TOP quality carbon Swedish steel

- SELECTED refined chemical composition

- HIGH CONSISTENCY carbide dispersion

- STRICTEST tolerances

Surface: bright polished

Tensile strength: 1960 ± 100 N/mm² (580 Hv)

Straightness maximum deviation: 1,0/3000 mm

Flatness maximum deviation: 0,3% across the strip width

Width tolerance (blade width < 50 mm): ± 0,10 mm

Width tolerance (blade width ≥ 50 mm): ± 0,15 mm

Thickness tolerance (blade thickness ≤ 0,152 mm): ± 0,009 mm

Thickness tolerance (blade thickness > 0,152 mm): ± 0,011 mm

Width tolerance (lamella): ± 0,025 mm

Thickness tolerance (lamella): ± 0,003 mm

Contact edge roughness: Ra 0,10 ± 0,05 μm

SILVER LABEL printing doctor blades

Stainless steel

- STAINLESS extra fine Swedish steel

- TOTAL oxydation and corrosion protection

- HIGH wear resistance

- PERFECT for water based inks and to solve rust problems

Surface: bright polished

Tensile strength: 1910 ± 100 N/mm² (565 Hv)

Straightness maximum deviation: 1,1/3000 mm

Flatness maximum deviation: 0,3% across the strip width

Width tolerance (blade width < 50 mm): ± 0,10 mm

Width tolerance (blade width ≥ 50 mm): ± 0,15 mm

Thickness tolerance (blade thickness ≤ 0,152 mm): ± 0,009 mm

Thickness tolerance (blade thickness > 0,152 mm): ± 0,011 mm

Width tolerance (lamella): ± 0,025 mm

Thickness tolerance (lamella): ± 0,003 mm

Contact edge roughness: Ra 0,10 ± 0,05 μm