Flexible Packaging & Labels

The Esko product portfolio supports and manages the packaging and print processes for brand owners, retailers, designers, premedia and trade shops, packaging manufacturers, and converters.

For 9 out of 10 retail packages, Esko solutions are used in packaging management, asset management, artwork creation, structural design, prepress, 3D visualization, flexo plate making, workflow automation, quality assurance, sample-making, palletization, supply chain collaboration and/or the production of signage and displays.

The Esko solutions consist of an extensive suite of software and two hardware product lines: CDI flexo computer-to-plate imagers and Kongsberg digital cutting systems, complemented with professional services, training and consultancy.

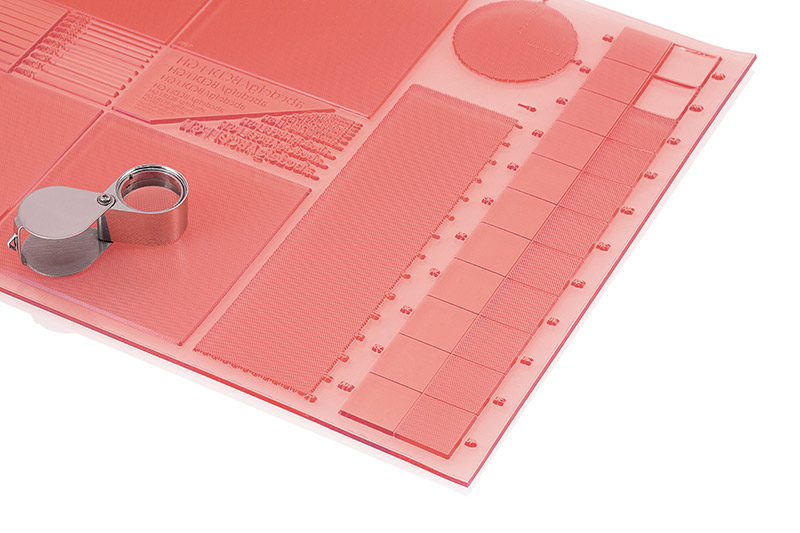

Producing the perfect plate

The Esko CDI Crystal is the basis for an impressive reduction of complexity in the plate room.

The new imager works with Crystal Technology, and is designed to connect seamlessly with the XPS Crystal digital UV exposure device.

The Esko CDI Crystal produces the perfect plate for all the flexo print applications that require high print output and stability on press.

GS Trading is a Luxembourg based company dedicated to supplying pre-press equipment, a complete range of letterpress, water and solvent flexographic plate making solutions. Based on years of design and manufacturing experience, its owner has a simple mission to provide well designed equipment at affordable prices. All of our equipment is designed and manufactured “in house”. Each customer request is taken into account.

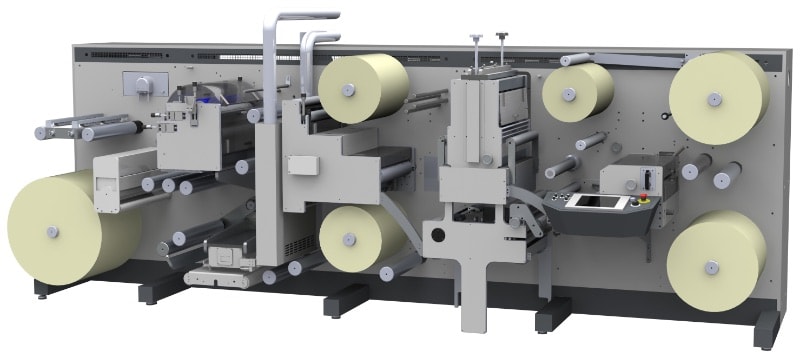

To meet the needs of the flexo platemakers, GS Trading manufactures processors for solvent washable and water washable flexo plates, systems with exposure, washout and drying units.

Performance Series

A Platform With Endless Opportunity

Designed to drive profitability in a highly competitive industry, the award-winning Performance Series product line redefines workflow productivity through its simple design, efficient waste savings and fast changeovers.

Innovation

The fastest selling platform press in narrow web history was developed with Business Responsive Technology to address your needs and impact your bottom line.

Stability

Over 800 worldwide installations place Mark Andy as a dominant force, stable provider and servicing authority of flexographic printing solutions.

Intelligence

Mark Andy AI packages support Industry 4.0 demands for enhanced automation.

Precision

360-degree registration adjustment and controlled ink densities produce high quality dots in a simple and repeatable fashion. Maintain your quality job to job, year over year, even in different production facilities.

Digital Series HD

Mark Andy’s production-class digital solution has been reimagined to bring greater levels of productivity and profitability to the modern label converter. Digital Series HD combines high-resolution digital print and best-in-class production capability into a single pass workflow. Zero tradeoffs in speed. No sacrifices in configurability.

The True Hybrid Advantage

Fully Integrated

Digital Series HD is a True Hybrid, meaning elements of digital and flexo within the machine are native to Mark Andy. What this means for you is a heightened user experience with a reliable partner. It is hardware and software designed to work together seamlessly to achieve unmatched benefits.

Enhanced Productivity

Printing at speeds up to 240 fpm (73 mpm), including white and combined with single pass inline converting, produces a higher throughput.

Revenue Generation

The combination of production speed, no click charges, and competitively priced consumables delivers the lowest total cost of operation with maximum return.

Flexibility

Digital Series HD is now available in 5 to 8 color configurations and can support integrated inline or future-proof near line converting options. It is custom designed for your exact digital workflow, printing, and converting needs with your growth path in mind.

Converting Solutions Rotoflex

Leaders by Design

Since 1973, Rotoflex has provided state-of-the-art inspection, slitting, rewinding and die cutting equipment to converters. Acquired by Mark Andy in 2008, the brand supports the end of the production line and powers rewind departments of our customers worldwide.

Innovative Finishing Solutions Kluge

Kluge, a pioneer in the print finishing and packaging converting market, consistently delivers innovative, reliable and profitable operations. The quality standard established back in 1919 remains at the forefront; Brandtjen & Kluge is committed to engineering, manufacturing and service to enhance workflows that support the ever-evolving needs of printers.

The Kluge line of equipment includes foil stamping, embossing and die-cutting presses, multi-function and high-speed straight-line folding and gluing equipment, with installations around the globe.

Rotoflex maintains a legacy of building reliable, productive equipment designed to increase profitability. With a broad range of products and services, Rotoflex has become known as an expert in vertical inspection equipment, manufacturing well-adopted machine models like VSI, the most installed inspection/rewind machine in the world.

MATRIX

The web viewing system is an area camera that moves across the web taking high quality snapshots of the whole running web. The 6 Mpixel camera resolution ensures fantastic quality and realistic colour reproduction. MATRIX can be loaded with multiple options such as statistical inspection, delta colour monitoring with ∆E, barcode verification, print repeat monitoring, UV coating visualization and transparent varnish inspection.

LYNEX

It is a true 100% inspection system that can be used as a stand alone system or integrated with MATRIX. LYNEX can compare live printing with the PDF file that has been used to produce the printed plates or the gravure cylinders. That provides the operator with the ability to verify if the print matches with the original file.

CHROMALAB

In-line real spectrophotometer, to monitor the colour trend of all printed colours; the system provides real time measurement and trends of Spectral curves, Density, dot gain, L*a*b*, ∆E

Xeikon CX500

Unbeatable productivity and quality.

Self-Adhesive labels

The Xeikon CX500 is the first digital label press based on a new generation dry toner platform that is designed around four key pillars:

Intuitive operator interactivity; consistent top notch quality; reliable best in class uptime and unbeatable productivity. For larger sized labels, labels requiring an opaque white or an extended gamut the Xeikon CX500 outperforms all high quality digital label presses in terms of productivity. This is achieved by its unique web width (up to 520mm – 20.47″), its full rotary printing technology and its 30m/min (98ft/min) printing speed.

Xeikon PX3000

Xeikon PX3000 combines our trademark quality, versatility and speed with the possibilities of inkjet. It’s Panther technology. It makes quality versatile. It’s very Xeikon.

- Automate your workflows

- Enjoy print media choice

- Make quality versatile

- Need speed? 50m/min at top speed

- PantherCure UV inks

Xeikon 3030

Designed to grow along with your business.

New to digital label printing? Here’s a label press for you: the Xeikon 3030. Entry level, and designed to be upgraded as your business grows.

- Print resolution: true 1200 dpi with variable dot density

- Variable printing width

- High productivity by full rotary printing

SR350 Slitter Inspection Rewinder

SR350 is a highly reliable, high-speed slitter inspection rewind machine. The SR350 features the newest in servo motion technology and a unique option for auto-set knifes. Designed for a wide range of SA labels on paper and plastic liners including the UPM PP30 and AD PET 23µm liners, booklet, tube laminate, Alufoil, Tyvek, cardboard, multilaminate.

Fully modular open concept allows to add the options such as 100% inspection camera, scanner bar code reader, ink-jet systems, register die-cutters, automatic slitting unit and waste vacuum ejector.

Quick set-up routines with the build in job-recall system ensure all systems are ready to run simultaneously, making it faster to change jobs.

Highlights:

- High speed up to 200m/min for efficient converting

- Automatic slitting available

- Code for laser & slitting – possibility to combine two machines working together thank to using the same barcodes. The knives are set automatically utilizing an information from barcodes.

- Advanced Nikka M1 label inspection system option, machine stops precisely within 10cm if detect any error

- Full rotary Die Cut option for white labels

- Length slitting station with 3x knives either (Shear / Razor / Crush)

- Domino inkjet printing option for codes producing

- Upgrade possible – more options available

- Easy web access and maintenance

DC500 Wide Web Semi-rotary Finishing

The DC500 offers maximum flexibility with fast and easy job changes between 330mm and 500mm web. The DC500 converting line has one distinct feature that makes it special: It runs web widths ranging from 500mm down to 100mm. In addition to this, the modular set-up makes it easy to add sections like e.g. the hot foil. So when investing in a new line, instead of having to guess about future needs – just prepare for it with the DC500. As your print-jobs change, your finishing line should not have to. The DC500 gives you huge flexibility on web sizes. The DC500 is a long-term investment for your current and future needs.

As digital label printing continues to grow, label-printing houses are realizing the need for all-inclusive digital printing systems that provide value-adding features for producing fully finished labels. The DC500 from Grafisk Maskinfabrik offers the ideal solution. A complete converting and finishing unit, this product was specially created for use with digital printing presses. The DC500 can be set up as an in-line extension to a digital label printing system, allowing the web to continue directly into the converter from the digital press. It can also be used as an off-line converting and finishing unit for jobs from other digital presses or conventional presses. It can even function as a printing press for specialized value-adding solutions.

The GM DC500 integrates the most advanced converting and finishing techniques available today. When used together with a digital label press, this innovative unit gives professional label printers a complete and versatile solution for high-volume digital printing.