Book / Newspaper Production & Commercial Printing

Book / Newspaper Production & Commercial Printing

As the world leader in prepress solutions, AGFA Graphics provides commercial, newspaper and packaging printers with the most extensive range of integrated premedia solutions, from complete computer-to-film/plate systems to digital contract proofing to PDF-/JDF-based workflow automation software. As the world’s largest plate assortment provider, Agfa Graphics produces state-of-the-art analog plates as well as thermal, visible-light, and chemistry-free digital plates for different printing applications.

Agfa’s solutions integrate consumables, hardware, software and services. After all, success is not just about a single piece of technology. It is about optimizing efficiency and integrating state-of-the-art products into complex workflows to simplify the process. Agfa Graphics creates these real-life solutions both through joint development and manufacturing partnerships with industry leaders and through targeted acquisitions that keep the company ahead by gaining technological expertise and market knowledge and broadening its portfolio.

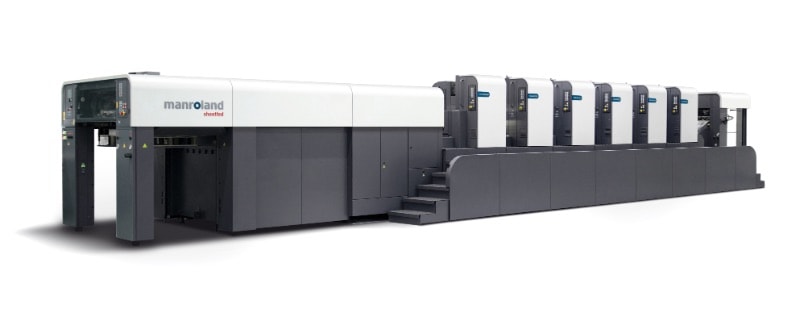

ROLAND 700 Evolution

The new standard in press technology.

The legend has evolved.

The ROLAND 700 Evolution supersedes both the ROLAND 700 HS and the ROLAND 700 Direct Drive, on an all-new platform. Designed from the ground up and incorporating a sleek, futuristic look, the latest generation ROLAND 700 incorporates many new technological developments, aimed to give printers unprecedented levels of efficiency, productivity, operation and quality.

Among these new developments are a newly designed central console with touch-screen control, a new feeder pile transport that cuts down on waste, Manrolands’ new suction belt sheet handling technology for a more even pile contour, all-new dampening units in the press, bearings that significantly reduce vibration and, when used with the sophisticated software for practice-oriented roller washing cycles, further reduction of downtime. The result is enhanced productivity and print quality alongside a further lowering of production costs.

Features & Benefits:

- Ergonomic operating user interface with touch-screens

- Direct Drive technology

- Total efficiency at 18,000 sph

- Optional 750 x 1,050 mm sheet size for maximum multiple-up images

- Feeder, delivery and dampening units specially designed for high-speed production

- Unique features include TripleFlow inking unit, intelligent speed compensation for inking and dampening units, effective anti-ghosting solutions

Newspaper Solutions

As the undisputed leading company in the market, manroland Goss web systems supplies newspaper presses and systems across the world. Products that have been printed using our systems reach over 400 million people in over 75 countries on all five continents of the world. It’s a fact that makes us feel proud, and with good reason. Thanks to our wide range of modular systems, our customers are able to develop a flexible response to market requirements.

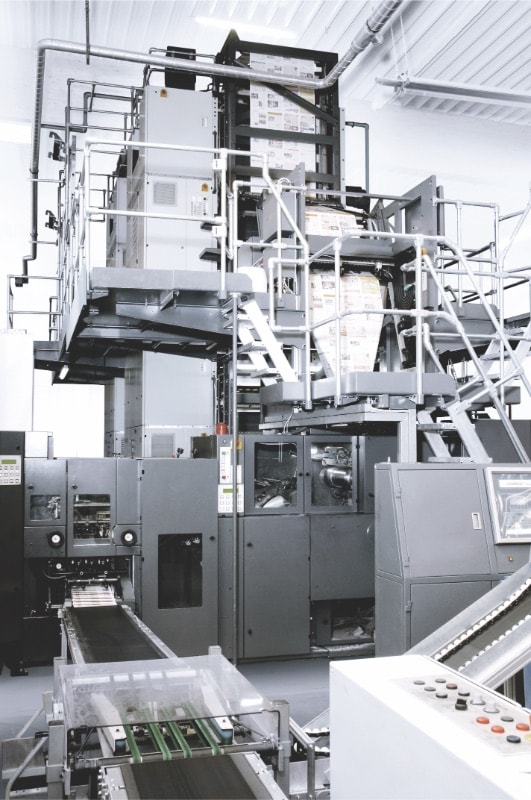

CROMOMAN

Hot and cold, day and night.

Efficiency and creativity are defining characteristics of the CROMOMAN 2-1. The high-end system is the fastest in its class. With its solid automation, the CROMOMAN turns out high-quality newspapers and magazines just as easily as heatset/coldset combination products.

Features & Advantages:

- Highest flexibility

- Minimal changeover times

- Rapid automatic web infeed (50 meters/164 feet per minute)

- Optimum register accuracy at high speeds

- For CROMOMAN press series: 2-1/3-1

- Broadsheet pages per web: 4

- Cylinder revolutions max./hour: 75,000

- web width: 965 mm/38 inch, circumference (mm): 630 mm/25 inch

- Optional additional equipment (examples): quarter fold; heatset dryer; IROLOC

UNISET

Modular system for a large variety of business models.

Achieve full capacity for the medium-volume segment: with a high net output, the UNISET can accomplish a wide range of jobs. Its talents run the gamut from newspaper printing to heatset products.

Features & Advantages

- Wide range of jobs

- Produces flexible contract jobs

- Production of different signatures

- Multiple and flexible press utilization

- Reduce waste, make-ready times and personal costs

- For UNISET press series: 2-2/3-2

- Broadsheet pages per web: 8

- copies/hour: 80,000

- web width: 965/1,280mm, 38/50 inch , circumference: 1,260 mm/50 inch

- Optional additional equipment (examples): quarter fold; heatset equipment; inkjet; IROLOC

Commercial Solutions

manroland Goss web systems is the leading supplier of commercial web offset presses. Our equipment enables companies working in this market segment to consolidate and further expand their position in the market-providing, of course, their production facilities are able to meet the requirements of a growing number of different products. Here, the ability to process orders at low cost but with superlative quality will play a predominant role in achieving success.

ROTOMAN HiPrint

The efficient 16-page icon.

The ROTOMAN HiPrint shines with its excellent price/performance ratio. The 16-page printing system was developed for all-round printers in dynamic markets as a cost-effective solution for printing magazines and supplements.

Features & Advantages:

- Excellent price/performance ratio

- Combines high performance with robust design

- Rapid production changeovers

- Less maintenance

- Consistent, premium quality

- Number of pages: 16

- revolutions/hour: 55,000

- Cylinder circumference: 546 – 630 mm. 21 – 25 inch

- web width: 965 mm. 38 inch

- Optional additional equipment (examples): PECOM-X, InlineDensity Control, sheeter

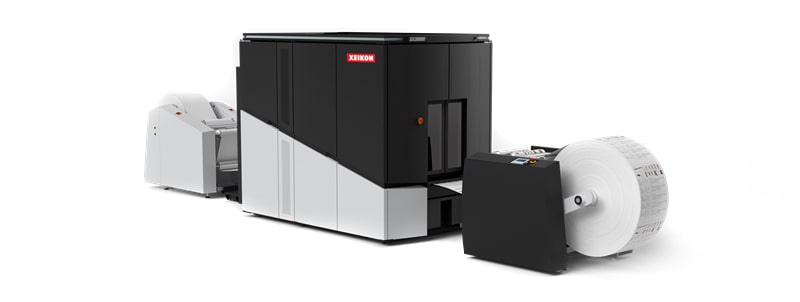

Xeikon SX30000

Offset printing quality with the highest resolution on the market.

Best-in-class substrate versatility without the need for coatings, primers or special papers.

New SIRIUS platform. Ground-breaking 5th generation dry toner single-pass-duplex platform. Robust base built for endurance, user friendliness, connectivity and serviceability.

Xeikon 8500

Digital is the new conventional

Brochures, posters, leaflets, packaging, small mailings… Shorter runs, tighter deadlines, greater variety – when you’re noticing that conventional technology doesn’t cut it anymore, it’s time to have a look at digital printing technology. Because a Xeikon digital press will have those challenges for breakfast.

Quality? Every Xeikon press prints at an impressive 1200 dpi.

Sustainability? Our dry toners make your documents recyclable and de-inkable.

Durability? The set-up is designed to grow with you and can be upgraded.

High productivity one-pass-duplex web fed printing.

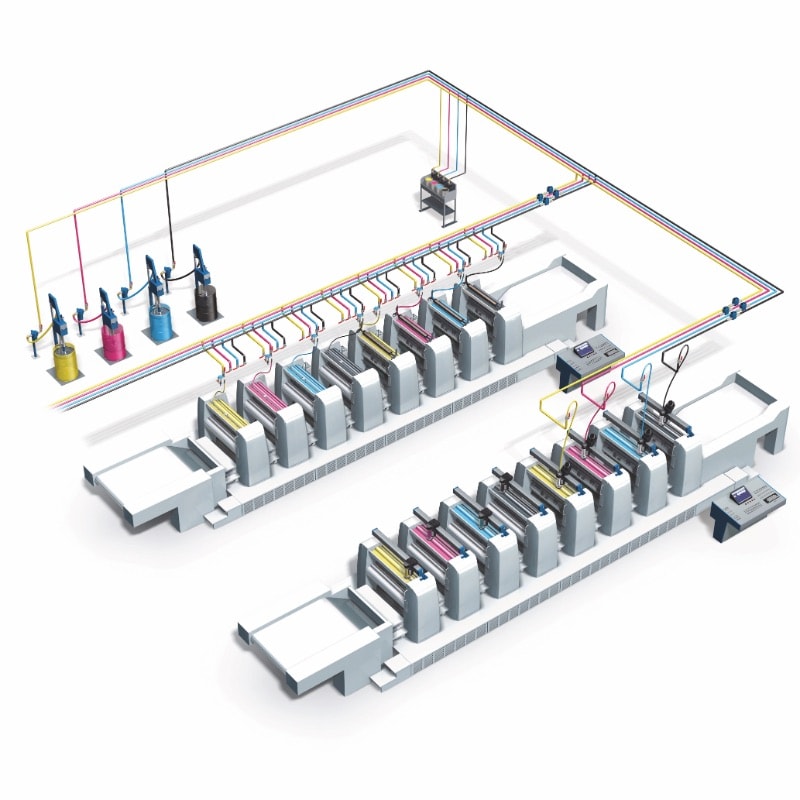

Specialists For Peripheral Units For The Print Industry

system supplier of cooling and fluid technology

technotrans SE has been a partner for printing companies and machine manufacturers for more than 40 years. Users rely on technotrans when it comes to controlling sensitive processes. Worldwide, more than 130,000 cooling and filtration systems are in use. Whether it is project planning, installation, commissioning or maintenance, our international team of experts knows all of the challenges that our customers must face on a daily basis.

From compact dampening solution circulators to central ink supply systems – all from one supplier:

- Dampening solution circulators & inking unit temperature control systems

- Filtration systems

- Central cooling systems

- Ink supply systems

- Coating preparation systems

- Water preparation systems

Book binding solutions

Between the manual production of books by craftsmen and industrial bookbinders, there is a big gap for small and medium-sized series and/or library binders. The manual craftsmanship supported by machines guarantees high quality even for small volumes.

At Schmedt you will find all machines required to make hard cover books:

- Block-making machine

- Case making machines

- Casing-in machines

Book Case Technology

The broad spectrum of HÖRAUF machinery offers the ideal machine for your application. Shortest change-over times, swiftness and greatest possible format ranges guarantee highest efficiency. Constructed in the proven durable and solid HÖRAUF design and optimized through years of experience and constant improvements.

BDM UNIVERSAL

Flexible in format and material selection

The BDM UNIVERSAL sets the scale world-wide for flexibility and reliability in the case making production. Its unique and constantly optimized design makes the UNIVERSAL a highlight of the BDM Series.

Format range:

Minimum: 105 x 170 mm

Maximum: 410 x 720 mm

Capacity: 60 cases/minute

BDM SPEED

High-Speed, High-Quality, High-End

The BDM SPEED is the result of our consistent orientation towards speed and quality in the high-performance range.

Format range:

Minimum: 130 x 190 mm

Maximum: 380 x 680 mm

Capacity: 85 cases/minute

High-Speed Cutter EUROCUTTER

With its further development of high-speed guillotines, EUROCUTTER® sets new standards for guillotines in view of the cutting process. The new SP3 guillotine-series complies with maximum standards, as single machine or in the center of an automated cutting line. The standard equipment leaves nothing to be desired, as almost everything is standard. With high vertical integration and the purchase of necessary and approved components of worldwide known leaders of technology, the EUROCUTTER® SP3 guillotine also sets new standards in quality.

Sturdy, powerful and long-lived due to tight and buckling resistant machine frame and the use of precision units for back gauge positioning, knife drive and guidance.

Efficient and economic due to high clamp opening, rapid back gauge speed as well as easy and fast knife change.

High precision due to a mutual linear back gauge guidance and precision ball screw for back gauge positioning.

Highest safety according to CE – machine building regulations.

Easy to use due to clearly arranged, modern operator panel, data input via pointer dot keyboard respectively Touch Screen Monitor (TM and TSM). The XLM type is equipped with a 18.5“ Full-Touch Screen Monitor in format 16:9. Symbols are consistent, uncomplicated and self-explanatory. Including format-programming and cutting bar ejector

Individuality due to a comprehensive range of products with 5 cutting widths from 800 to 1760 mm and 5 different control versions, offer the right product for each customer.

Professional laminators

ROBUST, RELIABLE, EASILY OPERABLE. Those are the professional Komfi laminators. Short machine adjustment times and, primarily, short changeover times are the major guarantee of economical operation. Thanks to the high technical standard of our machines, we guarantee you the high quality laminating on the very professional level.

Individual series of models are designed for various types of application depending on the size of orders to be processed; this is also reflected in the technical specifications of the machines. However, all KOMFI laminators are designed for PROFESSIONAL APPLICATIONS. The design of key processing components (e.g. the set of the laminating and pressure rolls with accurate temperature control) manufactured in the highest technical level possible offer our machines the best quality of lamination in various levels of operator automation, adjustment components, and software.

Spot UV varnishing of SPOTMATIC series

SPOTMATIC are spot varnishing machines that use the inkjet print technology for application of UV varnish onto the substrate. Therefore, this method of varnish application is suitable for lower-volume orders with complex varnish effects that require multi-stage print before curing, for example. The intuitive software is guarantee of easy operation and adjustment of the machine for a new order.